November 6, 2025

Dive into the fascinating world of Immensa, a company that’s making waves in the supply chain and manufacturing sectors. Immensa is well-known as a supply chain technology company or as an on-demand manufacturer. But what truly sets them apart is their unique ability to transform physical objects into digital assets. Let’s explore how they’re bridging the gap between the physical and digital!

Benefits of bridging the gap between physical and digital

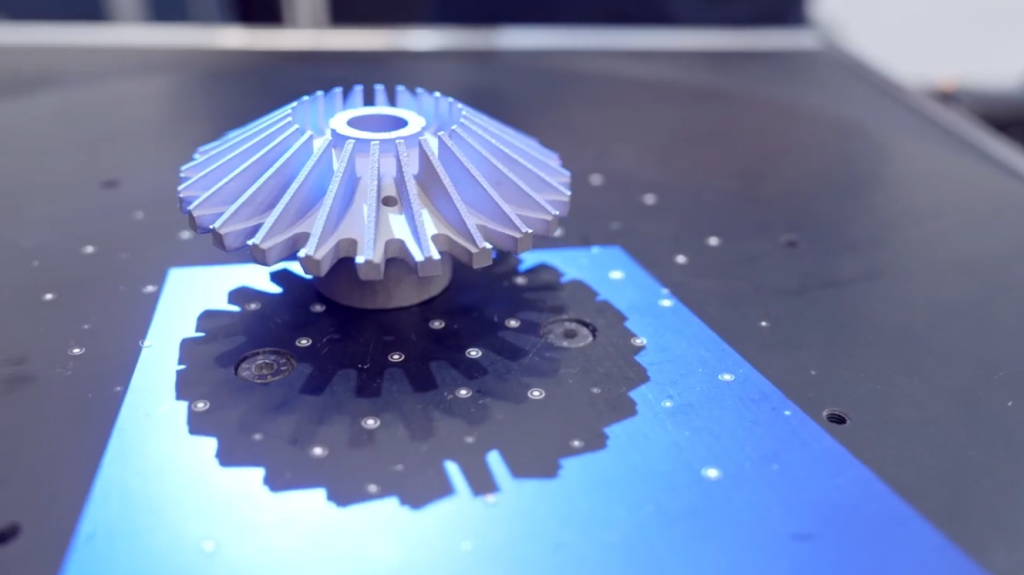

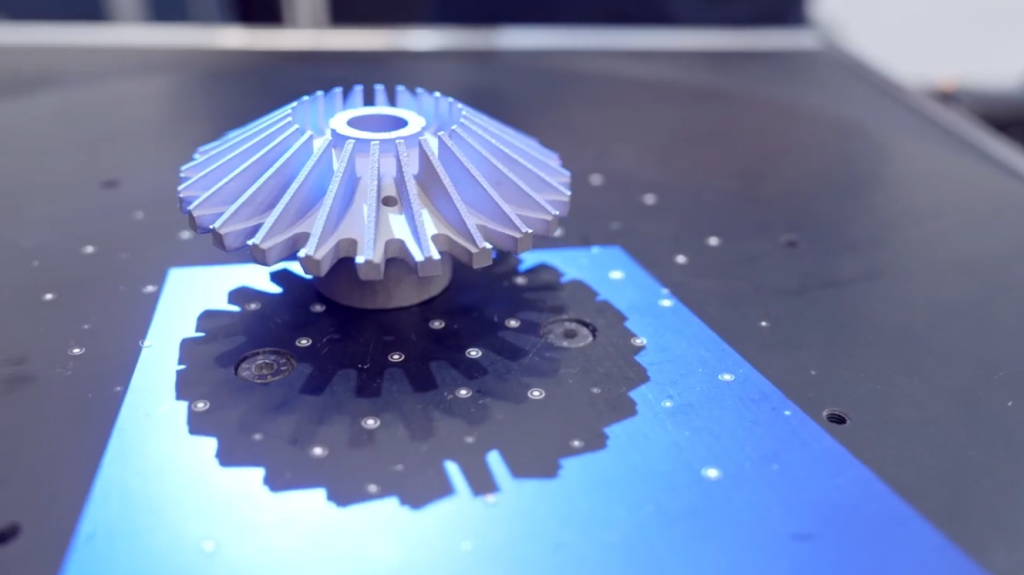

In our modern world, there’s a noticeable divide between what’s physical and what’s digital. Immensa saw a gap that needed filling – taking existing physical products and converting them into digital. Fahmi Al Shawwa, the CEO and founder of Immensa, is on a mission to create the largest platform for on-demand manufacturing, specifically tailored for the energy sector. Imagine a library of digital parts, complete with 2D and 3D drawings, manufacturing processes, and testing specifications. This digital repository is a game changer for international oil & gas companies, allowing them to produce, manufacture, and source spare parts on demand. Immensa aspires to meet the high expectations of their customers – some of the world’s largest oil and gas companies. They demand top-notch quality, safety, precision, and accuracy, all delivered in record time.Innovations for the oil and gas industry

One of the most thrilling aspects of working at Immensa is the opportunity to venture into uncharted territory. The team experiments and iterates, pushing the boundaries of what’s possible. It’s this spirit of innovation that drives breakthroughs and keeps the team excited about their work.

Tackling new challenges every day using state-of-the-art scanning technology

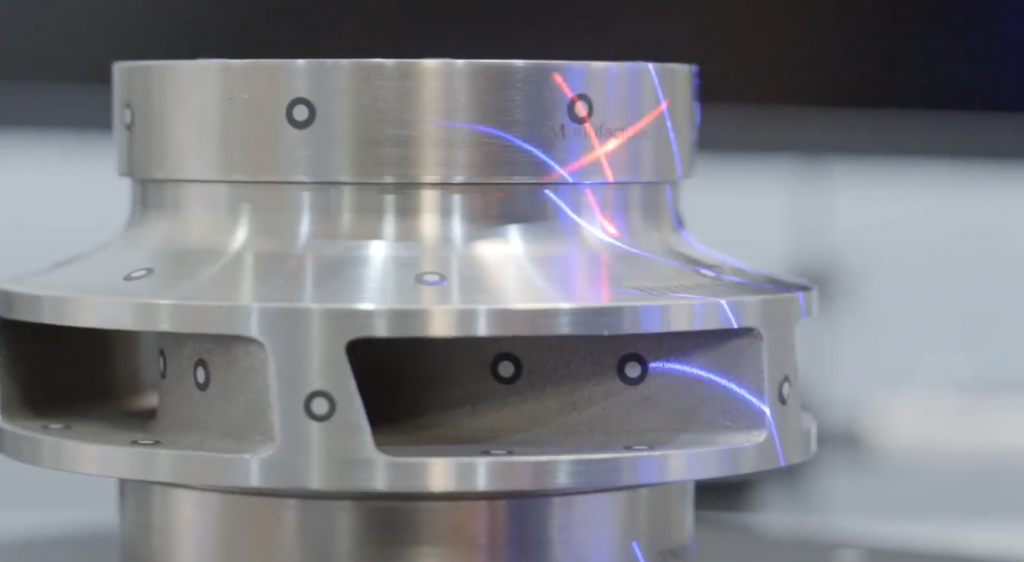

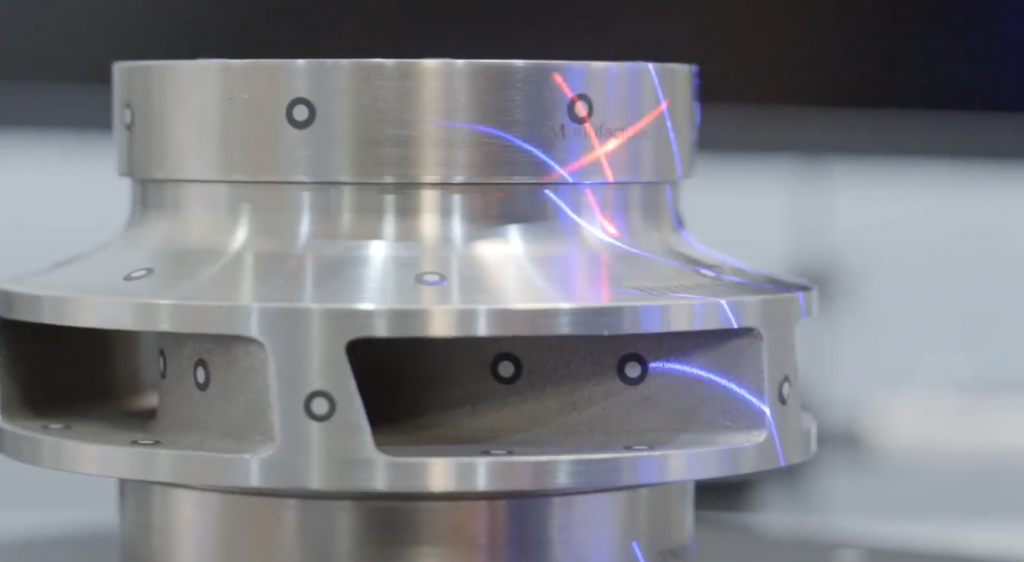

A key player in Immensa’s digitization process is the use of ZEISS scanning solutions. These advanced scanners are crucial for capturing the intricate details of spare parts, transforming them into accurate digital representations. By utilizing high-precision 3D scanning technology, Immensa ensures that every aspect of a part is documented, allowing for reliable manufacturing later on. The process begins with the careful scanning of a spare part. The scanners capture the full story behind the part, converting it into data that can be used for 3D modeling and manufacturing. This step is vital because any small error in the initial scan can amplify downstream, leading to potential issues in production. The team at Immensa is committed to getting it right the first time, which is why they rely on the precision of ZEISS technology. Ammar Khaled, the Digitization Team Leader, shares that every project at Immensa is a new challenge. Whether it’s reviving an obsolete part or repairing a damaged one, the work is never the same. The team manufactures polymer and metal parts, ensuring they serve their purpose and are reliable. With the help of ZEISS scanning solutions, Immensa can create accurate digital files that serve as the foundation for their manufacturing processes. This technology not only enhances the quality of the parts produced but also streamlines the entire workflow, making it more efficient.